Read the article

Read the article

Oxygen-Enriched Solutions for Pharmaceutical Wastewater

Expanding Pharmaceutical Wastewater Capacity with Oxygen Enrichment at PCI

How PCI Gases’ VSA Technology Increased Treatment Capacity and Cut Power Use in an Indian Pharma Plant

Overview: Scalable Pharmaceutical Wastewater Treatment with Oxygen Enrichment by PCI Gases

A pharmaceutical company near Hyderabad, India, faced growing production demands and needed to expand its wastewater treatment capacity without major infrastructure changes. After considering multiple options, the team chose to enhance pharmaceutical wastewater treatment with oxygen enrichment using PCI Gases’ DOCS 500-5 systems and its patented Low-to-Low-Pressure (LP2LP) injection technology.

By enriching the aeration tank with on-site generated oxygen, the plant successfully increased its throughput from 250 m³/day to 300 m³/day. In parallel, the system managed a higher COD load, which rose from 11,000 mg/L to 14,000 mg/L—all without modifying existing equipment. This upgrade helped ensure continued compliance with India’s Zero Liquid Discharge (ZLD) guidelines.

Introduction: Addressing Aeration Challenges in Pharmaceutical Wastewater Treatment

To meet strict environmental standards, the plant operated a treatment system that included:

An equalization basin collecting both production effluent and evaporator condensate

A primary and secondary aeration system, each followed by clarifiers

A final Reverse Osmosis (RO) unit for TDS removal and water reuse

However, the aeration tank faced two key challenges: limited dissolved oxygen (DO) levels and elevated basin temperatures (over 40°C). Despite using four surface aerators, the system often failed to maintain DO above 2 mg/L. These conditions restricted COD breakdown and placed strain on the biological process.

As the plant scaled production, these issues grew more severe. It became clear that a new approach was necessary. The operations team evaluated options and determined that oxygen enrichment would improve performance without requiring any major mechanical or civil upgrades.

PCI Gases Solutions:

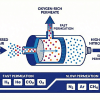

PCI Gases proposed a cost-effective and scalable solution: on-site oxygen generation using three DOCS 500-5 VSA units, combined with LP2LP venturi injection technology.

Key advantages of the system included:

On-site production of high-purity oxygen at just 0.3 bar (5 PSI), delivering up to 15% energy savings

A submersible recirculation pump that powered the venturi injectors and improved mixing in the basin

Dual injection manifolds, positioned on either side of the basin to provide even oxygen distribution and eliminate dead zones

A maintenance-free design with no moving parts in the injection system

Seamless installation that required no operational downtime

The system was fully integrated into the plant’s existing treatment infrastructure. This made it possible to increase treatment performance without expanding physical capacity.

🔗 Learn more about PCI Gases’ DOCS VSA generators

🔗 Explore LP2LP injection technology

Results of Oxygen Enrichment in Pharmaceutical Wastewater Treatment

Following installation and commissioning, the system began delivering results immediately:

COD tolerance increased from 11,000 mg/L to 14,000 mg/L

Flow rate improved from 250 m³/day to 300 m³/day

DO levels stabilized at 2.5–3.0 mg/L, even as temperatures reached 44°C

Final COD levels dropped to below 2,000 mg/L

These gains allowed the plant to shut down one surface aerator, which in turn lowered energy use from 120 kWh to 110 kWh per day.

Additionally, the improvements in aerobic treatment produced benefits downstream in the RO unit:

Fewer backwash cycles

Reduced chemical use

Longer membrane lifespan

Together, these outcomes translated into better performance, lower costs, and a faster return on investment.

Conclusion: Sustainable, Scalable Wastewater Treatment for the Pharma Sector

Thanks to PCI Gases’ DOCS VSA system and LP2LP injection solution, the pharmaceutical plant expanded capacity, improved effluent quality, and reduced its environmental footprint. Even better, the upgrade required no structural changes.

Looking ahead, the plant plans to automate oxygen delivery by integrating DO sensors and controllers. This step will enable real-time, load-based oxygen dosing, maximizing both energy savings and system responsiveness.

In the growing pharmaceutical industry, where strict discharge limits and high organic loads are common, pharmaceutical wastewater treatment with oxygen enrichment offers a clear path to long-term sustainability and compliance.

🌱 Let PCI Gases help you reshape your wastewater treatment process—efficiently, reliably, and sustainably.

📩 Contact our Global Water & Wastewater Treatment Director

Brendan van Wyk – bv*****@******es.com

Related articles:

PCI Gases to Launch New LP2LP Concept for Water Industry(Opens in a new browser tab)

Posted June 27, 2025