Read the article

Read the article

Unlocking Efficiency in Aquaculture with PCI On-Site Oxygen Generators

Oxygen Where You Need It, When You Need It: Unlocking Efficiency in Aquaculture with On-Site Oxygen Generation

Oxygen plays a critical role in aquaculture, ensuring optimal fish health, growth rates, and overall productivity. A reliable oxygen supply is essential for maintaining ideal water conditions. Traditional oxygen delivery methods—such as bulk liquid or cylinder supply—come with logistical challenges, high costs, and supply chain risks.

With on-site oxygen generation, fish farms can produce their own high-purity oxygen supply, eliminating reliance on external suppliers and gaining control over their operations.

How On-Site Oxygen Generation Improves Aquaculture Efficiency?

1. Ensures Continuous Oxygen Supply & Fish Health

Fish require precise oxygen levels for healthy growth and survival. Oxygen demand fluctuates based on stocking density, water temperature, and metabolic rates. On-site oxygen generation ensures consistent oxygen availability, avoiding supply chain disruptions and maintaining optimal fish health, feed conversion ratios, and growth rates. This leads to lower stress levels, better immunity, and higher yields.

2. Reduces Operational Costs

By utilizing concentrated oxygen, the amount of feed required to sustain the fish growth can be reduced, resulting in lower costs and increased profitability. Fish farms can significantly reduce costs associated with purchasing and transporting oxygen, leading to long-term savings.

3. Enhances Sustainability & Water Quality

On-site oxygen generation minimizes environmental impact by reducing the need for oxygen deliveries and storage-related losses, supporting a more sustainable and eco-friendly aquaculture operation. Additionally, maintaining ideal dissolved oxygen levels prevents fish mortality, reduces susceptibility to disease, and improves overall water quality.

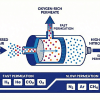

VSA Technology

To produce oxygen from air, PCI uses a proprietary Vacuum Swing Adsorption (VSA) process that eliminates many of the design problems associated with traditional on-site gas separation systems (PSA). Our innovative VSA system eliminates the need for process valves, feed air compressors, associated dryers and feed air filtering systems. Our robust VSA oxygen process extracts maximum sieve and power efficiencies = low cost (both CapX and OpX) high purity oxygen generation. Oxygen produced is 93% purity. Additional product/systems features include load following, remote monitoring and diagnostics along with an industry only 10-year warranty on the adsorber bed vessel. Average life span of our systems is 10-15+ years.

About PCI Gases

PCI Gases, headquartered in Riverside, California, is a global leader in advanced on-site gas generation systems. Specializing in Vacuum Swing Adsorption (VSA) technology for oxygen production, the company has been delivering innovative gas separation solutions since 1984. PCI Gases serves a wide range of industries, including medical, industrial, aquaculture, biogas, water treatment, and military applications.

With a mission to empower industries by providing autonomy in oxygen and nitrogen supply, PCI Gases helps clients reduce costs and improve sustainability. Their vision is to decentralize gas supply, offering economical and environmentally responsible solutions worldwide. Through a commitment to innovation and operational efficiency, PCI Gases continues to reshape industries and enhance the total cost of ownership for their customers.

Reshape Your Tomorrow!

Related articles:

For more information, please contact our Sales Directors:

– Fred Morgan (USA): fm*****@******es.com

– Ali Saputra (Corporate): as******@******es.com

– Tim Boulton (Europe and Middle East): tb******@******es.com

– Carla Cardenas (Latin America): cc*******@******es.com

– Pedro Nava (Mexico): en***@******es.com

– Andy Gows (Sub-Saharan Africa): ag****@******es.com

– Osama Ghazal (MENA): og*****@******es.com

Posted February 07, 2025